Interested in a tour of the 4id facility?

Fill out the form to register your interest for an in-depth tour, with demonstrations of the latest in contactless technologies, including RFID, Bluetooth Low Energy, and Sensor Tags.

Vision

Driven by a passion for investing in research, development and new technologies to support greater production efficiencies and customer demand puts 4id at the forefront of the RFID converting industry. Our vision is to support sustainable RFID development while exploring and evaluating new technologies for our customers to enhance our global product offering.

Smart & Sustainable Solutions

Working with innovative partners around the world, 4id is constantly looking to embrace opportunities for novel and sustainable applications and products which offer that little something extra. To this end 4id is working with partners to promote sensor enabled RFID products which can be used to confirm tamper/authenticity or wirelessly report temperature, strain, humidity, and light to name a few. Working towards a sustainable RFID future, 4id is looking to bring cutting edge approved compostable/biodegradable antenna printing capabilities to Australia.

To achieve the greatest sustainability benefit, RFID is best applied at the point of manufacture/growth for full lifecycle traceability, and these organisations are the focus for 4id’s future.

Smart Solutions

Sensor Tags

Sensor tags transmit both a unique ID and sensor data. Coded sensor tags can transmit readings such as temperature, strain, moisture and light. These tags use both HF & UHF frequencies.

Use Cases:

Greenhouses

Pharmaceutical packaging

Liquids/solutions bottling

Cold chain logistics

Food packaging/labelling

Provides:

Additional data collection

Improved monitoring and quality control

Predictive maintenance indication

Direct on Paper

Sustainable and biodegradable printed antennas and circuits, produced in-house, on low-temperature paper. HF, UHF, Dual Frequency.

Products manufactured using sustainable ecofriendly practices. Antennas are printed with no chemical etching. Biodegradable materials. In depth knowledge of Flex IC processes. Established capability in printed electronics.

Use Cases:

Can be used in 78% of use case applications as a direct replacement of traditional inlays.

Tamper Evident

Tamper Evident RFID labels are specially engineered using a special antenna design, that changes the way the inlay responds, indicating when tampering is attempted or has occurred. Once activated the tamper detection is irreversible. HF & UHF

Use Cases:

High value products such as wine & spirits

Consumer electronics e.g Mobile phones

Pharmaceutical packaging

Liquids/solutions bottling

Sustainable Solutions

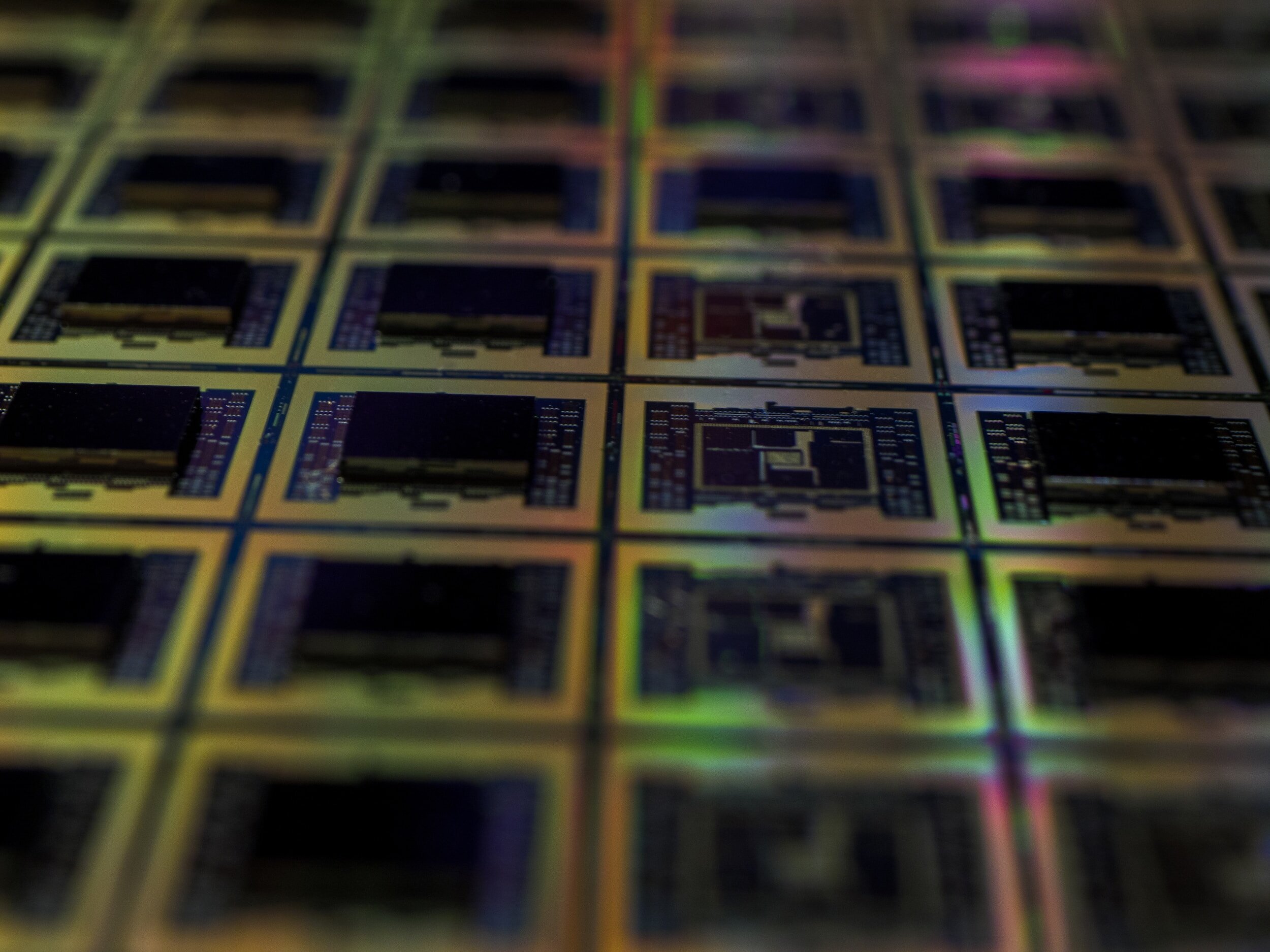

Integrated Circuits

An innovative technology which provides digital solutions across a wide variety of applications. Pragmatic flexible integrated circuits (known as FlexICs), bring cost-effective item-level digital traceability and interactivity to everyday objects. Sustainable, rapid production lead time can be sensor enabled; small cost effective Fab. HF & UHF.

Use Cases:

Fast moving consumer goods

Circular economy

Supply chain traceability

Authentication

Healthcare and medical

Authentication

Toys and games

Direct on Paper

Sustainable and biodegradable printed antennas and circuits, produced in-house, on low-temperature paper. HF, UHF, Dual Frequency.

Products manufactured using sustainable ecofriendly practices. Antennas are printed with no chemical etching. 100% eco-friendly.

Use Cases:

Can be used in 78% of use case applications as a direct replacement of traditional inlays.

Materials

Eco-friendly, compostable and biodegradable papers, laminates, inks and adhesives.

FSC certified materials, high percentage post-consumer waste products, bio-based products and PLA materials.

Use Cases:

We can source material solutions through our partners to solve all but the harshest label and tagging requirements.

Why 4id Solutions?

By employing sophisticated equipment and detailed processes, we can guarantee greater accuracy and efficiency compared to our competitors. The integration of multiple RFID readers & vision cameras throughout the production process allows us to achieve complete transparency, from receiving materials through to the final product. A Certificate of Conformance can then be generated, ensuring customer satisfaction.

At 4id, we pre-inspect all RFID inlays before converting labels, giving us and our customers confidence in our products. Further to this, our production methods and equipment have been fine-tuned to identify non-compliance throughout the production process, preventing bottle-necks that might occur in traditional methods, thus preventing fulfillment delays.

“As 4id are based in Australia, what is equally impressive is their ability to turn around production and design requests for our clients and have quick delivery to the USA for short term events. This gives our clients much more agility.”

“Thank you for sharing your vision of expanding the use of wireless technologies. As you know, we share this passion for expanding capabilities to serve critical industrial applications.”

“We highly value the opportunity to collaborate with your company and acknowledge the exceptional advanced manufacturing processes that 4id Solutions has developed.”

“The possibility to design, develop, and implement the proper manufacturing capabilities in Australia, as the primary base for exports, is encouraging as many of the materials and components are sourced from Asia.”