Discover 4id

4id Solutions specialises in the innovative manufacture of smart labels and tags using RFID & other contactless technologies.

As an established RFID converter with a proven global reputation for delivering high-quality RFID products, 4id continues to set the standards for what customers should expect from their converter.

Through an array of proprietary solutions and unparalleled production efficiencies, 4id presents innovations that transcend the realm of current industry thinking.

Vision

Driven by a passion for investing in research, development and new technologies to support greater production efficiencies and customer demand puts 4id at the forefront of the RFID converting industry. Our vision is to support sustainable RFID development while exploring and evaluating new technologies for our customers to enhance our global product offering.

Based in Wyong, servicing the world

4id Solutions specialises in the innovative manufacture of smart labels and tags using RFID & other contactless technologies.

Our distance from our key markets can be perceived as a disadvantage … BUT … our speed of delivery is our competitive advantage, making 4id a supplier of choice.

Partnering with the world’s best, for best-in-class outcomes.

Local and international suppliers

Manufacturing equipment

Industry Partnerships

Shipping and Logistics

Why 4id Solutions?

By employing sophisticated equipment and detailed processes, we can guarantee greater accuracy and efficiency compared to our competitors. The integration of multiple RFID readers & vision cameras throughout the production process allows us to achieve complete transparency, from receiving materials through to the final product. A Certificate of Conformance can then be generated, ensuring customer satisfaction.

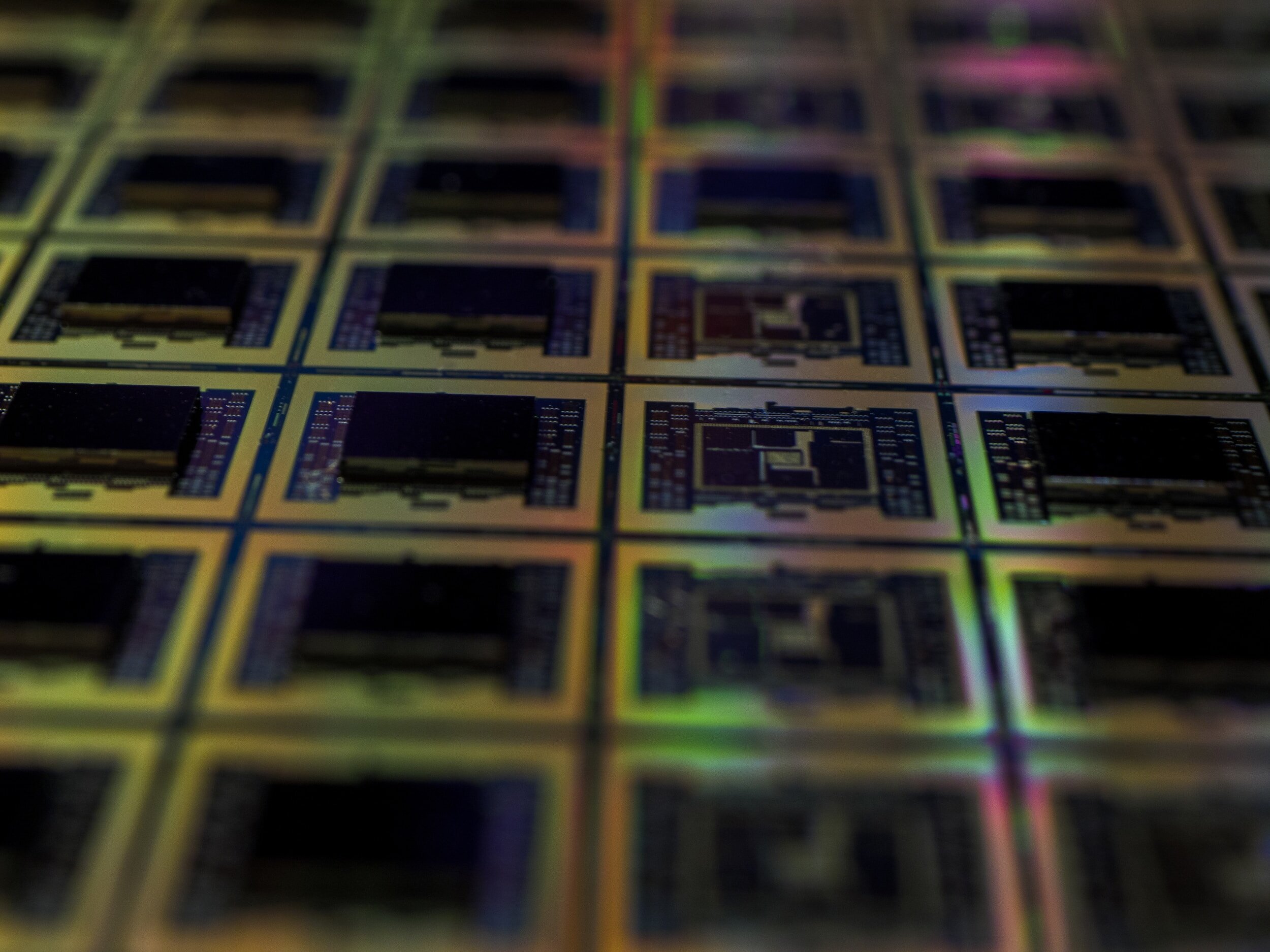

At 4id, we pre-inspect all RFID inlays before converting into labels, giving us and our customers confidence in our products. Further to this, our production methods and equipment have been fine-tuned to identify non-compliance throughout the production process, preventing bottle-necks that might occur in traditional methods, thus preventing fulfillment delays.

Point of Difference

A global exporter and highly respected converter using cutting-edge technologies

Wholesale RFID converters, converting tags using a variety of substrates and adhesives

Improving accuracy & efficiency at every step:

Vision cameras

Inline processors

Systems for reporting

Data verification & management

SafeGuard - complete product & order transparency

Turnaround times:

Scheduled - manufactured and delivered to meet planned orders

Flexible - adaptable to meet changes in circumstance or requirements

New York based customer relies on 4id for fast turnaround of RFID products over US suppliers

Sophisticated Equipment & High Performance Teams

Traceability & Efficiencies

SafeGuard

SafeGuard is a system that delivers real-time diagnostic capability to enhance production efficiencies. It elevates quality standards, provides efficiency gains in cost, time and waste. It delivers data-driven decision making while building robust business continuity. Through continuous data capture at points throughout a products manufacture, a digital copy of all components and sources is produced. By scanning the embedded RFID inlay, this information can be retrieved at any time in the future both for compliance and product authenticity.

Team Member - Glen

Glen, with a background in the Industrial/Commercial Electrical industry, brings valuable experience 4id. For the last year Glen has focused on expanding his knowledge on RFID technologies. His commitment to continuous learning and staying up-to-date with the latest advancements in the field has positioned him as a vital resource.

RFID Inspection

IP6/IP8

IP6 performs rigorous testing on RFID inlays and automatically replaces any that fail to meet our stringent requirements. It generates a comprehensive log containing unique inlay information, enabling us to easily trace the source details of any inlay in the future. Additionally, we are currently enhancing this machine to enable simultaneous encoding of inlays during the inspection process. This upgrade significantly enhances the machine's value and functionality by improving efficiency and streamlining operations.

Team Member - Shannon

Shannon joined us with a with a diverse background having previously worked in the construction industry. In just over two years at 4id he has become a versatile Production Technician, learning inlay inspection, encoding, and flexo press operations. Shannon actively seeks new challenges with attention to detail, problem-solving skills and a positive attitude.

Flexo Converting Equipment

RM3, RM5, HO7

4id’s RFID conversion machines known as RM3 and RM5 are where all the real magic happens, creating the highest quality RFID enabled labels, tags and wristbands with an efficiency second to none. Through a process of continuous improvements, these machines are now able to identify and report any imperfections in the job automatically allowing for the efficient editing of completed products to ensure 100% quality and adherence to customer requirements.

Team Members - Ross

Ross came to us with a completed Cert IV in Polymer Technology with a specialization in injection moulding. A member of the team for 2.5 years, Ross has become a skilled Printing Machinist, proficient in setting up and operating flexo presses, Converting/Encoding machines, optimizing and troubleshooting print presses.

High Resolution Digital Printing

HP Indigo

The HP Indigo allows 4id to produce any labels or wristband job on any substrate with easy and quick changeovers between applications. With the combination of high resolution and high-speed variable data printing, the press delivers high throughput and superior colour quality. The Indigo also allows for efficient production according to the Current Good Manufacturing Practices (cGMP) for pharmaceutical and security printing creating a robust, end-to-end security offering.

Team Member - Josh

Josh has a background as a Heavy Vehicle/Road Train driver, attesting to his work ethic and ability to handle demanding responsibilities. Having joined 4id two years ago, Josh has become a dedicated Printing Machinist, developing his knowledge and expertise in setting up and operating the digital printer and flexo presses.

Accuracy & Quality Assurance

Quality Control

Quality Control is to ensure all products and services meet specific standards and requirements. During manufacturing products are inspected and production processes are monitored to identify any defects or deviations from standards.

Team Member - Bonnie

Bonnie previously worked as a production engineer in the UK before relocating to Australia in 2000 to focus on raising her daughter. For the last 2.5 years Bonnie has quickly become an integral part of the team gaining expertise in setting up and operating Converting/Encoding machines and currently oversees the development and management of all QC processes, ensuring the highest standards of quality.

Smart & Sustainable Solutions

New Tech & Sustainability

Working with innovative partners around the world, 4id is constantly looking to embrace opportunities for novel and sustainable applications and products which offer that little something extra. To this end 4id is working with partners to promote sensor enabled RFID products which can be used to confirm tamper/authenticity or wirelessly report temperature, strain, humidity, and light to name a few. Working towards a sustainable RFID future, 4id is looking to bring cutting edge approved compostable/biodegradable antenna printing capabilities to Australia.

Team Member - Wayne

Wayne was recently appointed Innovation and Sustainable Technology Director. This newly created strategic leadership role is responsible for driving technology innovation, developing sustainable product strategies and identifying unique use cases within the organisation and abroad.

Production Capacity

Established output and spotlight on future growth

Current facility is 1,400 square metres

Daily capacity of 3 million tags

Systems and processes documented for Quality Management System and Health & Safety (ISO 9001 and 45001:2018 certification compliant)

Blueprint for satellite facilities

Centralised data management hub

2019 to 2023:

Increased output overseas

212% increase in staff across all departments

142% increase in floorspace with further developments underway

Increased utilisation from 58% to 74% since the installation of new equipment

Shipping & Logistics

Global Export Service

We have been shipping to the USA for years with minimal issues via both Sea and Air Freight

Our Freight Forwarder has the largest allocation on this service to Australia and has weekly slots available to ensure delivery to 4id

Freight Lead Times

Airfreight to Chicago is 5 days

Sea freight Chicago to Sydney 32-35 days via Long Beach, California

Sea Freight Sydney to Chicago 48-53 days via Philadelphia

Freight Efficiencies

Returning freight to the USA via the East Coast is the best option due to fewer delays and cancellations and the ability to get the freight from Port to Chicago or other destinations in the USA without delays

We can save on freight costs and delivery times by amalgamating incoming freight into BCN's, packed in either Chicago, Long Beach or Philadelphia.

Smart Solutions

Sensor Tags

Sensor tags transmit both a unique ID and sensor data. Coded sensor tags can transmit readings such as temperature, strain, moisture and light. These tags use both HF & UHF frequencies.

Use Cases:

Greenhouses

Pharmaceutical packaging

Liquids/solutions bottling

Cold chain logistics

Food packaging/labelling

Provides:

Additional data collection

Improved monitoring and quality control

Predictive maintenance indication

Direct on Paper

Sustainable and biodegradable printed antennas and circuits, produced in-house, on low-temperature paper. HF, UHF, Dual Frequency.

Products manufactured using sustainable ecofriendly practices. Antennas are printed with no chemical etching. Biodegradable materials. In depth knowledge of Flex IC processes. Established capability in printed electronics.

Use Cases:

Can be used in 78% of use case applications as a direct replacement of traditional inlays.

Tamper Evident

Tamper Evident RFID labels are specially engineered using a special antenna design, that changes the way the inlay responds, indicating when tampering is attempted or has occurred. Once activated the tamper detection is irreversible. HF & UHF

Use Cases:

High value products such as wine & spirits

Consumer electronics e.g Mobile phones

Pharmaceutical packaging

Liquids/solutions bottling

Sustainable Solutions

Integrated Circuits

An innovative technology which provides digital solutions across a wide variety of applications. Pragmatic flexible integrated circuits (known as FlexICs), bring cost-effective item-level digital traceability and interactivity to everyday objects. Sustainable, rapid production lead time can be sensor enabled; small cost effective Fab. HF & UHF.

Use Cases:

Fast moving consumer goods

Circular economy

Supply chain traceability

Authentication

Healthcare and medical

Authentication

Toys and games

Direct on Paper

Sustainable and biodegradable printed antennas and circuits, produced in-house, on low-temperature paper. HF, UHF, Dual Frequency.

Products manufactured using sustainable ecofriendly practices. Antennas are printed with no chemical etching. 100% eco-friendly.

Use Cases:

Can be used in 78% of use case applications as a direct replacement of traditional inlays.

Materials

Eco-friendly, compostable and biodegradable papers, laminates, inks and adhesives.

FSC certified materials, high percentage post-consumer waste products, bio-based products and PLA materials.

Use Cases:

We can source material solutions through our partners to solve all but the harshest label and tagging requirements.

“As 4id are based in Australia, what is equally impressive is their ability to turn around production and design requests for our clients and have quick delivery to the USA for short term events. This gives our clients much more agility.”

“Thank you for sharing your vision of expanding the use of wireless technologies. As you know, we share this passion for expanding capabilities to serve critical industrial applications.”

“We highly value the opportunity to collaborate with your company and acknowledge the exceptional advanced manufacturing processes that 4id Solutions has developed.”

“The possibility to design, develop, and implement the proper manufacturing capabilities in Australia, as the primary base for exports, is encouraging as many of the materials and components are sourced from Asia.”